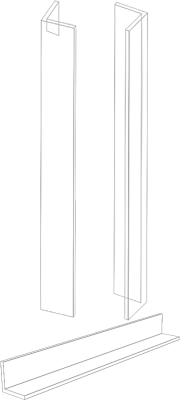

At Skipper Limited, our Hot Rolled Structures form the backbone of World-Class Transmission Towers and engineered infrastructure. Through our state-of-the-art Rolling Mill in Uluberia, West Bengal, we produce Mild Steel (MS) and High Tensile (HT) Angles, Channels, Flats, H-Beams, and I-Beams that meet international standards—IS, ASTM, BSEN, and AS.

Our integrated value chain – from billets to galvanized towers – ensures dimensional accuracy, superior strength, and traceable quality. The plant’s automation, Industry 4.0 readiness, and sustainable manufacturing systems make Skipper one of India’s most advanced producers of hot rolled sections for critical infrastructure.

| Type | Sections Produced | Grades | Standards |

|---|---|---|---|

| Angles | Equal & Unequal | IS, ASTM, BSEN, AS | Dimensional tolerance as per IS 2062 & ASTM A36 |

| Channels | U, C, and Custom | IS, ASTM | ± 0.5 mm precision on dimensions |

| Flats | Custom thickness | IS, BSEN | 5 - 150 mm width range |

| Beams | H-Beam, I-Beam | IS 808, ASTM A992 | Up to 400 mm depth |

| TMT Bars (for captive use) | Fe 500, Fe 550 | BIS | Controlled chemistry and strength |

All raw materials are spectro-tested for every billet and bloom, ensuring chemical and mechanical integrity. Continuous in-process quality checks guarantee surface finish, straightness, camber, and radius precision.

Skipper manufactures re-rolled structures by re-heating billets and blooms, ensuring precise shaping and consistency.

We manufacture profiles according to specific customer requirements, including custom lengths and adherence to various international standards.

After rolling, all structures are properly straightened and packed as per customer specifications, ensuring ready-to-use, high-quality materials.