We have initiated the GreenCo Certification, a globally recognized framework developed by the Confederation of Indian Industry (CII) to assess and enhance environmental performance.

This certification will help Skipper to progress towards net zero carbon and waste goals, enhance water efficiency, and improve supply chain greening and product stewardship.

Avoided Emissions

in emission intensity per

metric ton production

Our waste heat recovery system and recuperators installed during FY 2023-24 are expected to reduce significant amount of coal consumption required for heat generation in reheating furnaces, resulting in substantial reduction of CO2 in the coming years.

As a part of the transition to lower carbon intensity fuels, we phased out the usage of furnace oil and transitioned to Light Diesel Oil (LDO), Low Sulphur Heavy Stock (LSHS), and Liquified Petroleum Gas (LPG).

In FY 2023-24, we further reduced LSHS and LDO consumption, prioritizing LPG as our primary fuel source, to promote lower carbon-intensity fuel.

We are conducting Life Cycle Assessment (LCA) for towers and poles, our two major products to identify and understand embedded emissions at the product level.

We have initiated a phased replacement of CO2 gas with an 80:20 Argon-CO2 mixture, which helps reduce greenhouse gas emissions.

We are evaluating the introduction of an induction furnace in tower bending to replace the existing gas and fuel-based furnace, as part of our sustainability initiatives

We currently have a total solar capacity of 2.59 MW. During the year, we added 400 KW at the Uluberia facility and 750 KW at the Guwahati facility. We have generated a total of 2,056,280 kWh of renewable energy leveraging solar plants during the financial year. Our goal is to further expand our rooftop solar plants across our organization by 2025.

At Uluberia facility, we implemented daylight harvesting system with rooftop sheets, to enhance the Lux levels within our working areas from approximately 250 to 300. This eco-friendly initiative significantly reduced energy consumption and enhanced the working environment.

Effective water management is essential for ensuring the long-term viability of ecosystems, supporting communities, and maintaining the operations of industries.

Water is a critical input in our manufacturing process. Being aware of the risks from drought and water scarcity, we have evaluated the risks using tools such as the aqueduct water risk atlas, Water Risk Filter (WWF), and analyses from the Central Ground Water Board (CGWB) and State Water Investigation Directorate (SWID) for the state of Bengal. This evaluation has provided vital insights into current and projected water-related challenges that the company will face in the coming years.

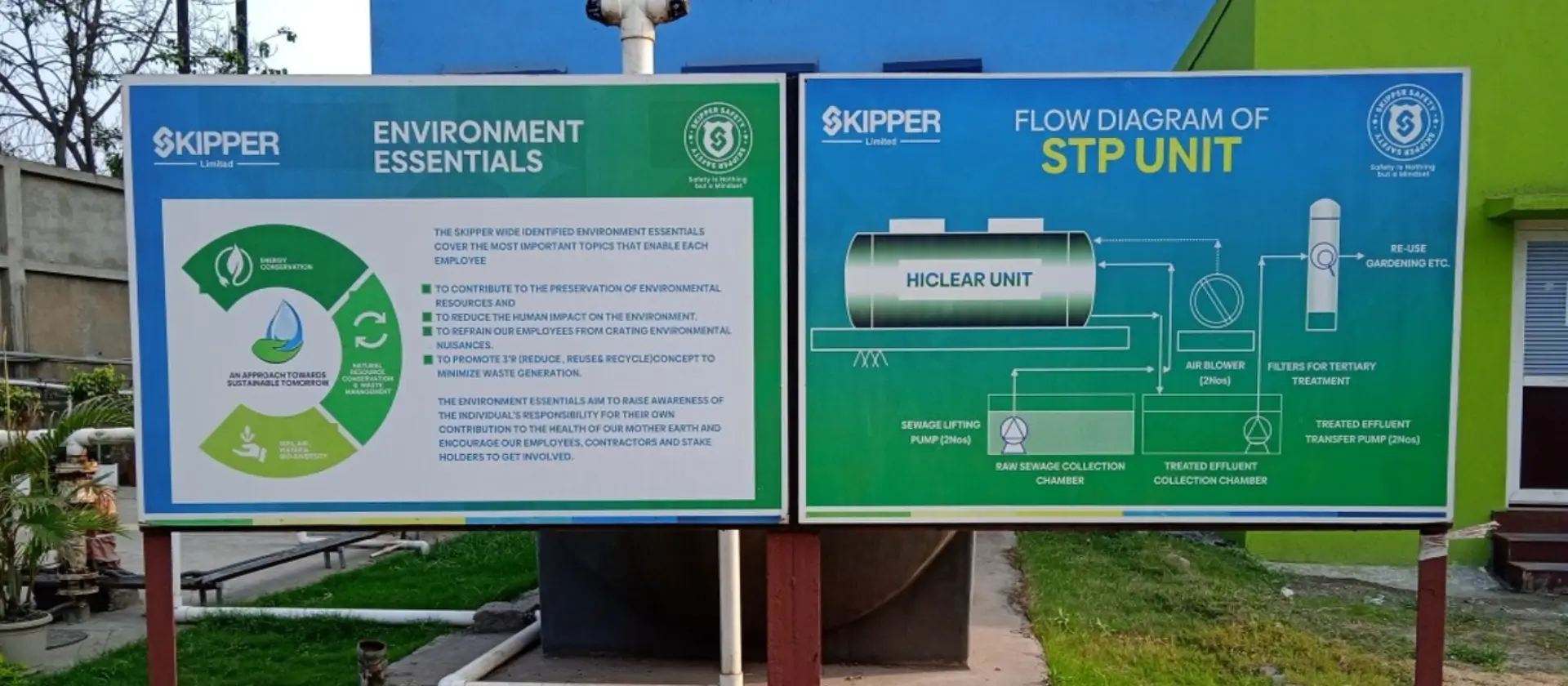

In FY 2022-23, we established a sewage treatment plant (STP) with a capacity of 60 KLD to treat domestic wastewater from the worker’s residential building.

The treated water is used in the galvanizing process.

The water is effectively used for dust suppression and gardening purposes.

Based on requirements, the treated water undergoes reverse osmosis (RO) for further purification. The RO-treated water is then used in quenching processes.

The water rejected by the RO process is repurposed for dust suppression.

During the same year, we installed a cutting-edge 40 KLD Effluent Treatment Plant (ETP) equipped with Moving Bed Biofilm Reactor (MBBR) to augment treatment efficiency. MBBR technology utilizes engineered bacteria for filtration.

In FY 2023-24, a 150 KLD capacity ETP for iron removal was installed at the Uluberia unit to facilitate the reuse of iron-contaminated water in our in-house processes specifically the rolling mill unit. To ensure stringent compliance with environmental standards, we meticulously test the water quality at every stage of the effluent treatment process.

Skipper’s waste management practices are designed to minimize the environmental impact of waste generation and disposal. We focus on reducing waste at the source, monitoring waste generation, segregating waste for better management, and ensuring responsible disposal. We emphasize safe handling of hazardous waste.

Our ERP systems systemically track waste data from generation to disposal. Our hazardous waste includes, Zinc ash and dross, used oil, and ETP sludge. We partner with CPCB and SPCB-authorized agencies for safe disposal supported by thorough documentation.

We have upgraded our ETP with advanced treatment technologies such as Lamella Clarifiers, MBBR, and tertiary processes, resulting in a reduction of sludge generation.

We strictly adhere to international codes for all our products, and our extensive range of certifications underscores our commitment to meeting global standards.

Our engineering product design process is rigorously analysed using advanced software to proactively address any potential on-site failures. To eliminate fitment issues, we conduct horizontal assembly for 100% of our structures. When necessary, we also perform full-scale load testing to validate the robustness of our designs.

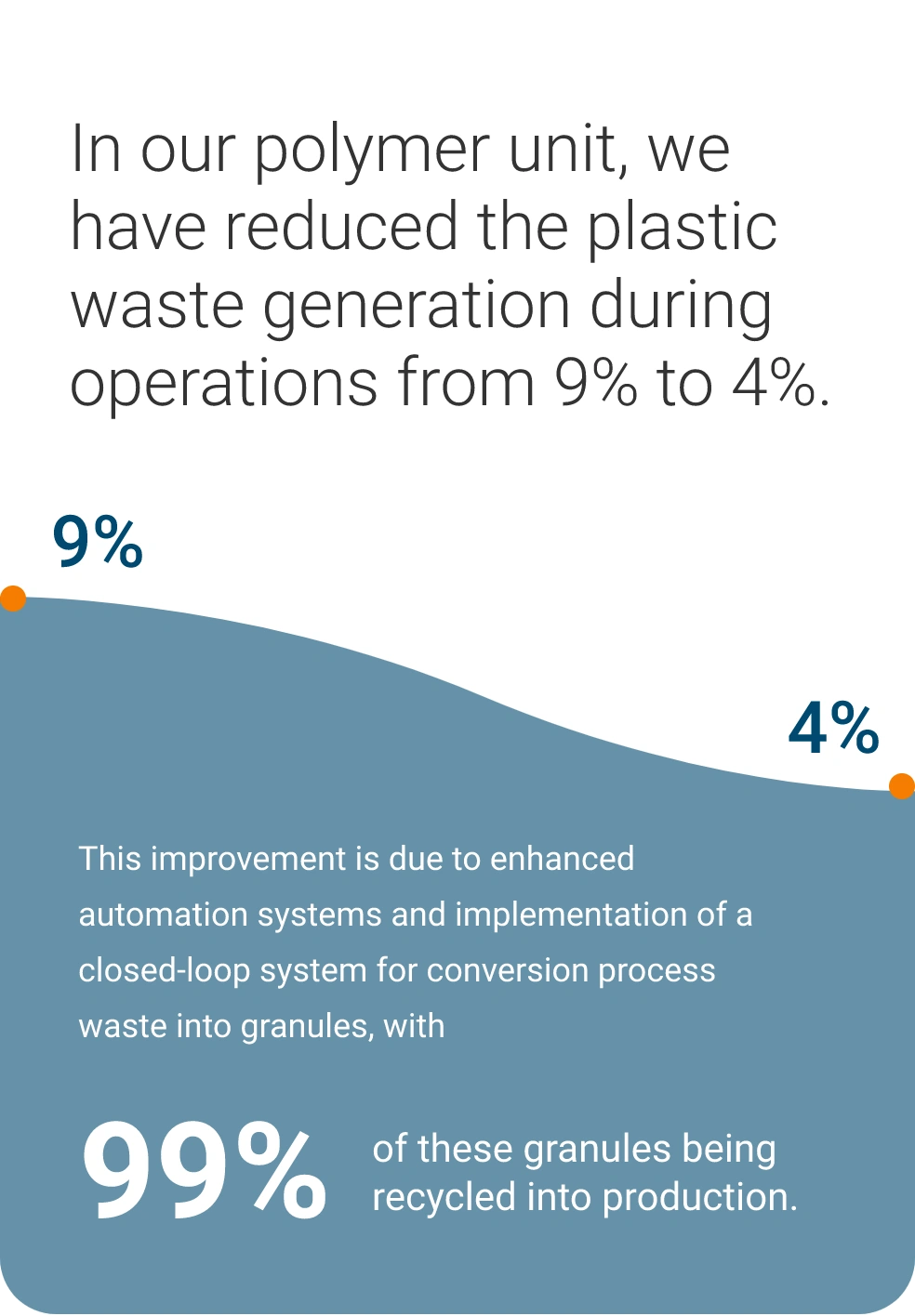

For polymer products, we prioritize the use of high-quality ingredients and additives. Through precise extrusion and stringent testing, our pipes meet industry standards for durability and longevity, enhancing customer safety, stakeholder trust, and our brand reputation. In response to the growing concern over lead contamination in water supply systems, our pipes are certified by NSF 14. Additionally, we have received Greenpro certification for our CPVC pipes and fittings. These measures underscore our commitment to high-quality, safe, and environmentally responsible engineering practices.