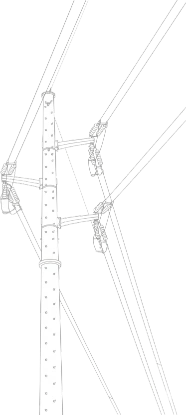

Skipper Limited is a Trusted Global Manufacturer of steel utility structures for Power Transmission and Distribution. With decades of expertise in Engineered Poles, Standard Class Poles and Tubular Substation Structures. Skipper delivers advanced, space-efficient, and durable solutions designed to meet diverse infrastructural demands—from 33kV distribution lines to 765kV transmission networks.

Our poles combine superior engineering, high-grade steel fabrication, and advanced galvanizing technology to ensure long-term performance and corrosion resistance. Whether for urban power corridors Skipper’s pole structures are designed to minimize land footprint, simplify installation, and maximize reliability.

Metric Ton Poles Supplied All over the World

Skipper Limited offers high-quality tubular steel Engineered Poles, engineered for strength and reliability in high-voltage power transmission. Designed to withstand extreme weather conditions, our poles ensure long-lasting performance and uncompromising quality.

Skipper Limited provides tubular Standard Class Poles designed for efficient, durable power distribution in medium- and low-voltage networks. Offering excellent resistance to corrosion and environmental stress, these poles guarantee long-lasting performance in challenging conditions.

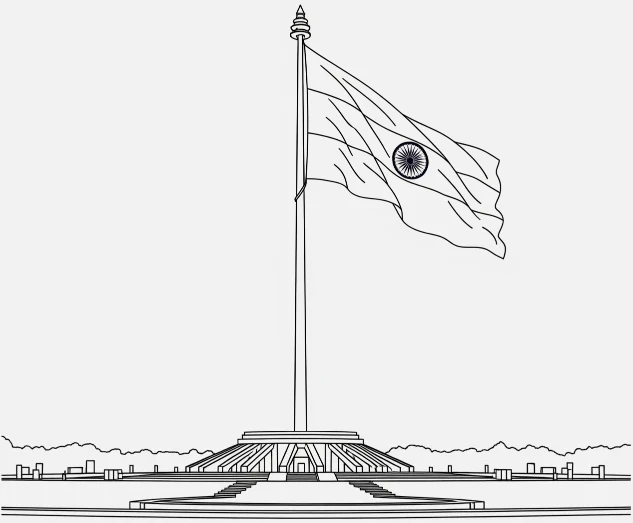

Installed India’s tallest flagpole (418 ft) at Atari-Wagah Border

Competitive Pricing – As the only fully backward-integrated T&D structure manufacturing company, Skipper manages every aspect of our value chain, including angle rolling, fabrication, galvanizing, prototype assembly, and full-scale load testing. This comprehensive approach enables Skipper to offer competitive pricing and excellent lead times.

Exceptional Lead Times – Depending upon the complexity of the structures on any given project (i.e., WPE/standard class poles vs. custom-designed poles) and the relative quantity of structures on a project, we can provide exceptional lead times typically ranging from 17 to 28 weeks ARO, which is considerably better than the current norms across the industry.

Industry Standard Design – Utilizing industry standard design and drawing software, our in-house team of skilled engineers and professionals ensures every structure is developed to the highest industry standards—consistently meeting and exceeding customer expectations.

NABL and ISO Certified Laboratory – With our own NABL (National Accreditation Board for Testing and Calibration Laboratories) accredited and ISP certified laboratory, and with our extensive experience with customers of 65+ countries, Skipper consistently upholds the highest quality standards across all product lines.

Full-Scale Load Testing – Skipper operates two adjacent full-scale load test beds, providing the flexibility to prioritize and efficiently accommodate customer testing requirements.

.webp)

Supply of 115 kV, 150 Custom-Designed Structures with 20 Design Variants for a Project, USA

.webp)

Supply of 115 kV, 7 Structures for Accelerated Delivery to Support Winter Construction, USA

.webp)

Supply of 115 kV, 61 Poles with Designs Delivered Within Compressed Schedule, Canada

.webp)

Supply of 400 kV M/C and D/C, 'H' type Monopoles for three Project Sites for Gurgaon Palwal

.webp)

Supply of 220 kV and 400 kV D/C Monopoles for Utility Diversion and Shifting

.webp)

Supply of 400 kV D/C Monopoles in ROW-Prone Areas near Mumbai under the WRNER Project

.webp)

Supply of 400 kV and 220 kV Transmission Lines for 1500 MVA 400 kV GIS Substation under the Kharghar

.webp)

Supply of 220 kV M/C and D/C Monopoles along SG Highway under the Torrent Power Network

.webp)

Supply and Installation of 220 kV M/C and 132 kV M/C Monopoles for the PITCMRL