Since its inception, Skipper has consistently invested in Research & Development to foster innovation and excellence. Our Dedicated R&D Centre in Howrah, West Bengal, is recognized by the Department of Scientific & Industrial Research (DSIR), Ministry of Science & Technology, Government of India. Backed by Strong R&D Infrastructure and Expertise, Skipper has pioneered several first-of-its-kind products in India, reinforcing its position as an industry innovator. Through continuous R&D efforts, the company continues to strengthen its leadership in the transmission and distribution sector.

Looking ahead, Skipper is expanding its R&D initiatives not only to enhance its existing portfolio but also to diversify into new products and services. Our primary objective is to remain future-ready and a pioneer in technology, creating sustainable value for our customers and stakeholders.

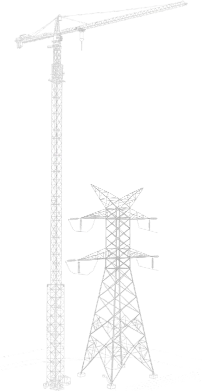

Skipper’s Tower Testing Station is one of the Largest in The World, offering comprehensive testing solutions for transmission towers, monopoles, and other critical infrastructure. The facility is equipped to test Towers up to 1200kV and 120m in height, making it a preferred prototype testing centre for contractors and manufacturers.

In 2020, Skipper further strengthened its innovation ecosystem by commissioning one of the World’s Largest Tower Testing Stations to support advanced R&D activities. The Testing Station is equipped with State-of-the-art infrastructure to test all types of transmission towers and poles.

Most widely used for its modularity, durability, and ease of installation.

Big saving on steel where land availability is not a constraint.

Smaller footprint, Aesthetic, Best Suited for City Centres/Highways.

(CICA (Composite Insulated Crossarms) – An innovative technology towards compact designs.

Integral part of the transmission system.

Two Fully Independent Transmission Tower Test Beds at One Location - This unique dual setup enables simultaneous testing, ensuring faster project turnaround and unmatched efficiency within the industry. Customers can even witness two tests on a single visit.

Dedicated Prototype Manufacturing Plant - Supports seamless testing operations, ensuring timely fabrication and delivery of tower components.

Robust Backward Integration - A dedicated in-house Rolling Mill gives Skipper complete control over raw material availability — ensuring efficiency, reliability, and optimum delivery time for every project.

24x7 Operations - Operating round the clock, Skipper is the only Testing Station in the world with continuous operations throughout the year, ensuring optimum turnaround time and enhanced testing efficiency.

Globally Accredited Excellence - Skipper holds ISO/IEC 17025:2017 accreditation - ensuring globally recognized standards of measurement accuracy, operational safety, and testing reliability.

State-of-the-Art Loading & Measurement System - Skipper’s Testing Station is equipped with a SCADA-based control system and VFD-driven electrical winches, ensuring safe, precise, and efficient load application during testing.

Proven Track Record - Skipper has successfully served nearly 60 utilities across 21 countries, demonstrating its global reach and trusted performance in tower testing and validation.

Prototype Tower Fabrication and Load Testing for 500 kV Standard Transmission Towers, Sarawak Energy

Design and Support of 138 kV 2-Circuit Tangent Tower, CenterPoint Energy, United States of America

Prototype Manufacturing and Testing of 500 kV HVDC OHTL Towers for Interconnection Link, Saudi Elect